Control application

This section is split into two : turtle graphics and the usually known as turtle graphics e of sensors to control motor application .

1. Turtle graphics

In the computer language called “Logo” and is now usually known as turtle graphics. It is essentially the control of the movement of a ‘turtle’ on a computer screen by a number of key instructions which can be typed in .

This is the common logo command :

Note : using combinations of these commands makes it possible to draw all kinds of different shapes .

Example one :

Shape to draw

Logo command :

PENDOWN

Forward 60

Right 90

Forward 60

Right 90

Forward 30

Left 90

Forward 30

Right 90

Forward 30

Using REPEAT n ENDREPEAT

logo command logo command

PENDOWN PENDOWN

FORWARD 30 REPEAT 4

Right 90 FORWARD 30

FORWARD 30 RIGHT 90

Right 90 ENDREPEAT

(option 1) (option 2)

Note : both option above will draw above will draw the shape to the left . in option 2, however , does less step using Repeat and ENDREPEAT

Logo command

PENDOWN

REPEAT 6

FORWARD 30

LEFT 60

2. Applications using sensor

There is a difference between monitoring and controlling an application using a computer and sensors . in this cases, sensors are used to send data to a computer where the data processed- it is what happens next where the difference occur:

In Monitoring , the computer again reviews the data from the sensors ( by comparing it to data stored in memory) and updates its files and ?or gives a warning signal if the value are outside given parameters.

in control applications, the computer again reviews the data from the sensors ( by comparing it to data stored in memory). But if it is outside from the range ( acceptable range . the will send a alert.

They also use ADC ( analogue to digital converter)so that the computer can understand and process the data from the sensors.

Example :

Monitoring example : monitoring patient vital signs in a hospital

• Sensors read key vital signs ( such as pulse /heart rate , etc .)

• The data are converted into digital using an ADC

• The data stored in computer data

• The computer compares the data in the form of graphs / or digital read outs.

• An alarm is activated if there is something wrong

• The system continues to monitor the patient until the computer turned off

Advantage

• the computer will not forget to take reading

• they response very fast

• always work 24 hours

• the reading will be more accurate

• Readings can be taken more frequently if they

Robotic

Computer-controlled manufacturing has revolutionised the way products are made. Modern factories are full of robots; everything is automated.

In a modern factory the only people you will see are a few engineers who are responsible for keeping the robots and other machinery running smoothly.

This is very different to old factories, where everything was done manually by human workers.

What is an Industrial Robot?

When you think of the word ‘robot’, you might picture a human-shaped robot with arms, legs and a head – the sort you see in sci-fi films. However this is not how the sort of robots used in factories look.

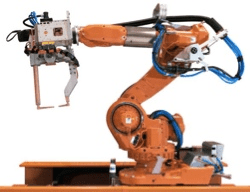

Robots used in factories are called industrial robots, and they come in a wide variety of shapes and sizes.

The most common type of industrial robot looks a little bit like a human arm. The robot has joints (like our shoulder, elbow, and wrist) and some sort of manipulator / device on the end of the arm (where our hand would be).

The robot’s joints are powered by very strong electric motors. These motors are controlled by a computer.

How Are Robots Used in a Factory?

Robots in factories are used to:

lift heavy items into from place to place